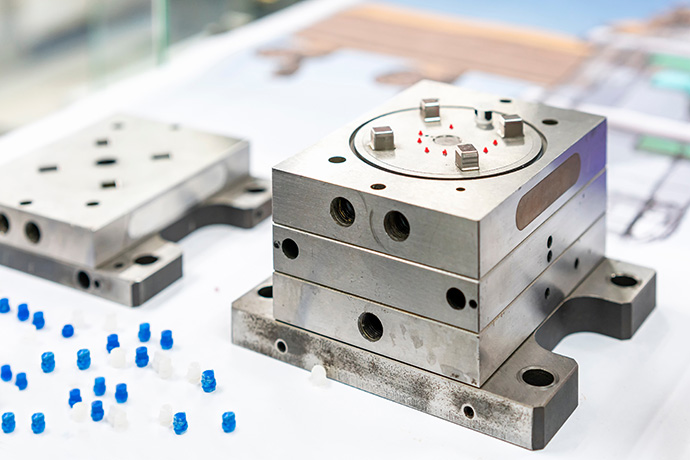

One of the most critical parts of the mold making process involves the fitting and assembly portion of production. This allows us to put your mold together to ensure it is functioning properly. Mold assembly requires comprehensive understanding of the injection molding process as well as mold structure.

Before assembling each mold, our experts check and verify all components. It’s critical to make sure all surfaces are polished accordingly to avoid any de-molding issues. The assembly process also allows our experts to check all sharp edges, verify mold gate and runner sizes and ensure all part surfaces are properly vented.

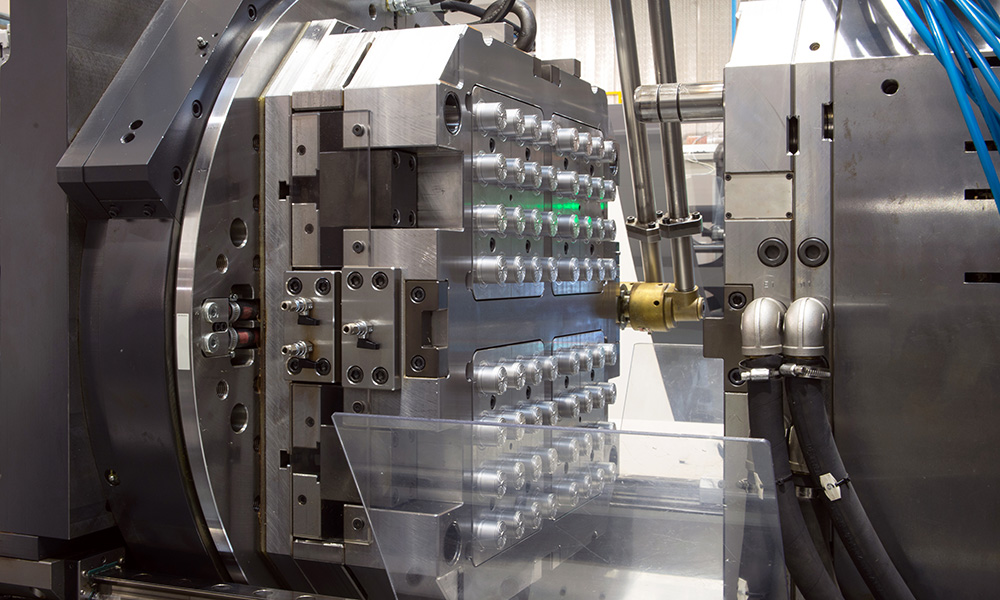

We work side-by-side with our clients on even the most complex of molds, keeping to their production schedules to completely accommodate any maintenance needs. With steel or aluminum molds, timing is key. We can proactively work around your shutdown times to get your parts up and running again.

Our dedicated staff has the ability to take their knowledge directly to the problem for on-site repair and maintenance. Our experts have in-depth experience and specialized skills when it comes to the mold process, resulting in a zero percent chance of mistakes during disassembly and reassembly.